Balanced Spiral Woven Belt

Balanced Spiral Woven

Established & trusted design keeps your process on the move.

Wire Belt Company’s Balanced Spiral belt is an extremely popular mesh design, found in almost every manufacturing industry with a wide ranging number of possible applications. Benefits of Balanced Spiral belt include straight-running operation, an excellent strength to weight ratio and an extremely wide variety of mesh specifications to suit each individual application.

Balanced Spiral gains its excellent tracking properties by employing an alternating pattern which prevents the belt from pulling to one side. Lateral movement within the belt is reduced by the use of specially crimped rods which hold each spiral coil in place.

Balanced Spiral is most commonly supplied as friction-drive belt; however certain meshes can be supplied as Positive-Drive, allowing sprockets to engage with the belts mesh. Alternatively, we can supply Balanced Spiral with chain edges for high load applications.

Cross-Flights and Side Plates are available for inclined applications or product separation requirements. Wire Belt Company also supplies Double Balanced Spiral belting, for applications with particularly high load and/or for products which require a narrower aperture than is possible with standard balanced spiral belts.

Other Specialised Belt Style Applications:

·Lehr Belts for Glass Annealing

·Swarf Filter Belts

·Loose link and Ferrule chain edge for Cryogenic Freezers

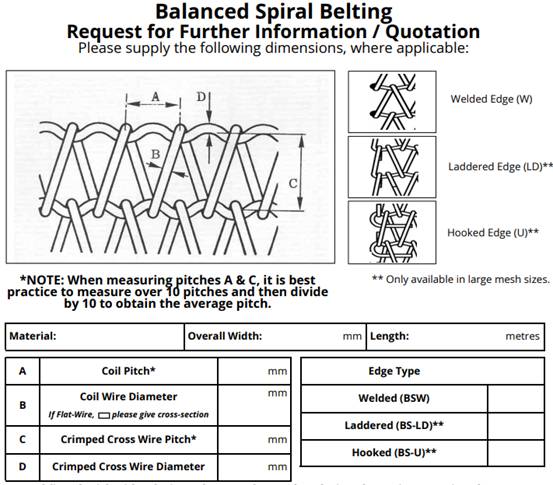

Standard Balanced Spiral (BS)

The assembly consists of alternating left and right hand coils with each coil interconnecting with the next by means of a crimped cross wire.

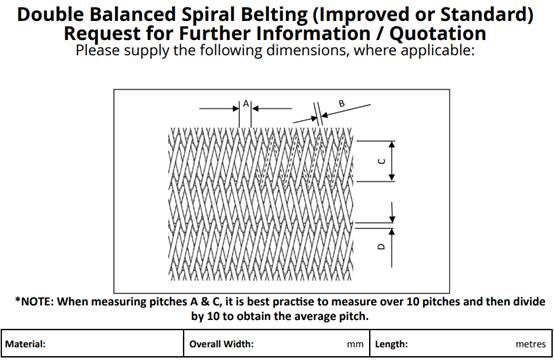

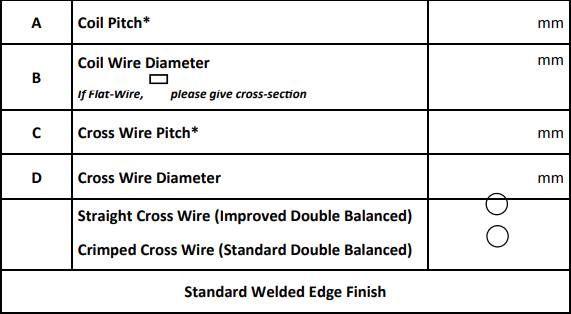

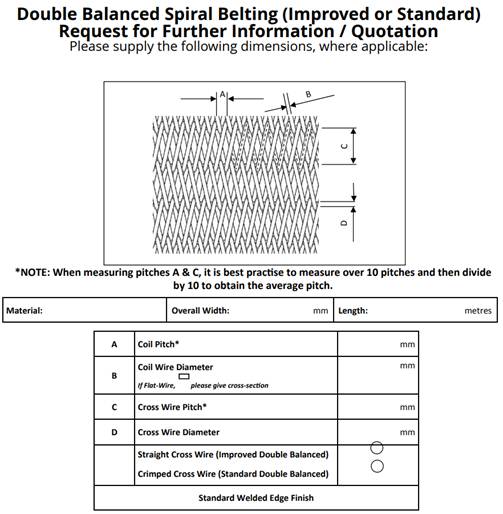

The double balanced assembly is similar to standard balanced spiral but uses coil pairs of each handing intermeshing and then link by means of the crimped cross wire with pairs of intermeshing opposite hand coils on a repeat pattern down the length. This style allows for closer pitching of coils across the width for small product handling.

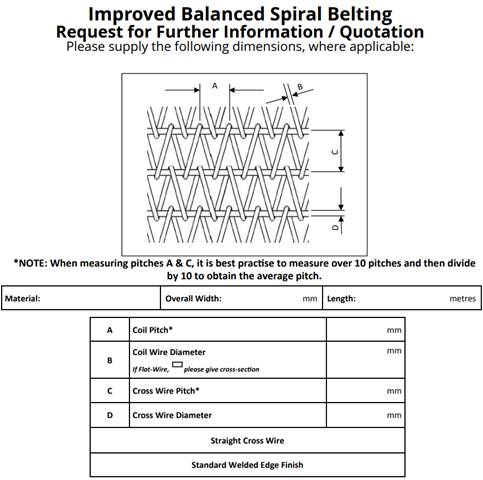

Improved Balanced Spiral (IBS)

The structure of this belt is similar to “Standard Balanced Spiral” but uses a straight cross wire with single interconnecting coils in a repeat pattern of left hand/right hand down the length. This assembly allows for a closer pitching of single coils across the width for small product handling.

Improved Double Balanced Spiral (IDBS)

The structure of this belt is similar to “Double Balanced Spiral” but uses a straight cross wire with double intermeshing coils of each handing interconnecting by means of the straight cross wire in a repeat pattern of left hand/right hand coils down the length. This assembly allows for a closer pitching of coils across the width for small product handling.

Edge Availability

Welded Edge (W) - mesh only

This is the most common and economical edge finish. With welding together of both the coil and crimp wires there are not cut wire ends.

Laddered Edge (LD) - mesh only

Less common than the welded edge the laddered edge is often used where welds are not desirable for the application. It is also an option in applications where welding facilities are not available. The belt edge is also smooth and allows more belt edge flexibility. It is also more efficient in high temperature applications as the laddered edge is not under operational strain in use and therefore less prone to fracture. Generally this edge finish is only available for meshes with a relatively large crimp wire pitch down the length.

Hook Edge (U) - mesh only

Also less common than the welded edge type the hook edge is often used where welds are not desirable for the application. It is also an option in applications where welding facilities are not available. The belt edge is also smooth and allows more belt edge flexibility. Generally this edge finish is only available for meshes with a relatively large crimp wire pitch down the length.

Chain Edge Driven Mesh

Along with the above mesh edge finishes these meshes can be driven by side chains using cross rods which are located through the mesh coils and then through chains at the edges of the mesh. The types of cross rod finish at the exterior of the side chain are as follows:

With welded washer

This is the most common and economical styl

e of finish to a chain edge belt and comprises of a central mesh carried through the system by means of edge chains with carrier cross rods through both mesh and edge chains. The cross rods are finished at the outside chain edges with a welded washer

With Cotter Pin & Washer

Although less economical this type of assembly allows the customer or service personnel the ability to replace the edge drive chains when the mesh and rods are still serviceable. The assembly comprises of a central mesh carried through the system by means of edge chains with carrier cross rods through both mesh and edge chains. The cross rods are finished at the outside with a drilled hole to allow the fitment of a washer & cotter pin. It also allows the repair replacement of sections of belt without the need to grind off rod heads and weld back together.

NB: For greater width stability of rods to chain it is the norm, where possible, to supply the cross rods turned down to go through the edge chains.

Various other styles of chain edge finish include:-

Cross rod welded flush to the hollow pin of the side chain. This is not a preferred standard but may be necessary where width between conveyor side frames and other structural parts create a limitation where "welded washer" or "washer & cotter pin" cannot be used.

Cross rod welded flush through drilled hole on inner plates of roller conveyor chain.

In general the chain edge driven belts as shown above are available with 2 styles of edge chain:

Transmission Chain

Transmission chain has a small roller. The chain edge can be supported either on the chain side plates or by means of a profiled rail to go between the side plates and support on the roller or alternatively without support where the mesh is supported close to the edge.

Conveyor Roller Chain

Conveyor Roller Chain has a large roller. The chain edge can then be supported on a flat angle edge wear strip with the chain roller rotating freely along the conveyor length.

| Mesh Type | Specification Coding | Nominal Belt Thickness (mm) | Lateral Pitch of Coil wire(mm) | Coil Wire Dia. (mm) | Crimped Cross Wire Pitch down length (mm) | Crimped Cross Wire Dia (mm) |

| BSW-PD | 18-16-16-16 | 7.7 | 16.94 | 1.63 | 19.05 | 1.63 |

| BSW-PD | 18-14-16-14 | 8.9 | 16.94 | 2.03 | 19.05 | 2.03 |

| BSW-PD | 30-17-24-17 | 7.3 | 10.16 | 1.42 | 12.7 | 1.42 |

| BSW-PD | 30-16-24-16 | 6.7 | 10.16 | 1.63 | 12.7 | 1.63 |

| BSW-PD | 42-18-36-18 | 6.0 | 7.26 | 1.22 | 8.47 | 1.22 |

| BSW-PD | 42-17-36-17 | 6.0 | 7.26 | 1.42 | 8.47 | 1.42 |

| BSW-PD | 42-16-36-16 | 6.4 | 7.26 | 1.63 | 8.47 | 1.63 |

| BSW-PD | 48-17-48-17 | 6.1 | 6.35 | 1.42 | 6.35 | 1.42 |

| BSW-PD | 48-16-48-16 | 6.4 | 6.35 | 1.63 | 6.35 | 1.63 |

| BSW-PD | 60-20-48-18 | 4.0 | 5.08 | 0.91 | 6.35 | 1.22 |

| BSW-PD | 60-18-48-18 | 5.2 | 5.08 | 1.22 | 6.35 | 1.22 |

| BSW-PD | 60-18-60-18 | 5.6 | 5.08 | 1.22 | 5.08 | 1.22 |

All specifications are supplied with welded edge only.

Other Specialised Belt Style Applications:

Lehr Belts for Glass Annealing

Swarf Filter Belts

Loose link and Ferrule chain edge for Cryogenic Freezers

| Standard Material Availability (Mesh Only) Material | Maximum Wire Operating Temperature °C |

| Carbon Steel (40/45) | 550 |

| Galvanised Mild Steel | 400 |

| Chrome Molybdenum (3% Chrome) | 700 |

| 304 Stainless Steel (1.4301) | 750 |

| 321 Stainless Steel (1.4541) | 750 |

| 316 Stainless Steel (1.4401) | 800 |

| 316L Stainless Steel (1.4404) | 800 |

| 314 Stainless Steel (1.4841) | 1120 (Avoid use at 800-900°C) |

| 37/18 Nickel Chrome (1.4864) | 1120 |

| 80/20 Nickel Chrome (2.4869) | 1150 |

| Inconel 600 (2.4816) | 1150 |

| Inconel 601 (2.4851) | 1150 |

PRE:无上一篇

NEXT:Chain Link Belt